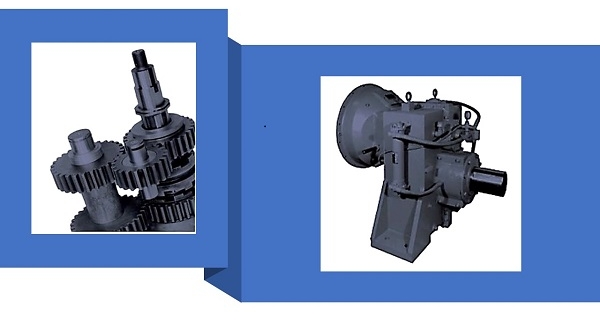

Precision Engineered Speed Reducers

Compact and rugged, Cotta’s engine mounted precision engineered speed reducers are designed to meet the demands of modern diesel engines. Cotta speed reducers match the optimum engine speed to optimum driven equipment speed, allowing your engine and load to both operate at ideal efficiency. Typical uses include pumps, dredges, compressors, crushers, drills, and high-performance machinery for oil & gas, construction, mining, and other industrial applications. Our heavy-duty gearboxes are designed for use with diesel engines, electric motors, PTO”s, and other prime movers. See more below:

- Standard case is cast iron. For custom cases, fabricated stress relieved steel is used

- Lube pump and heat exchanger provided

- Various flywheel couplings, including over center clutches, torsional couplings, drive plates, and custom

- SAE housings from 00 to 5 for minimum installation space. Remote mounting available

- Standard keyed stub shaft. Options include splined, extended length, flanged, or customer specified. Shaft can be 12, 6, or 9 o’clock to the input

Cotta speed reducers require rear supports, and are designed to be driven clockwise facing the input shaft. For us to recommend a speed reducer, we need to know the following:

- Input speed

- Ideal output speed

- Flywheel housing size

- Flywheel connection requirement

- Direction of rotation

- Type of driven equipment

Choose from our standard models, or we will design one for your application. Either way… Cotta will meet the challenge.

LEARN MORE: POPULAR COTTA SPEED REDUCERS

Leave a Reply

Want to join the discussion?Feel free to contribute!