State-of-the-Art Testing Capabilities

Cotta continues to solidify our reputation as a preferred high-performance gearbox supplier by consistently improving our current line of products along with developing new innovative products. We systematically and comprehensively monitor the quality of all internal processes. First-piece inspection is conducted on every machining sequence, starting at the source to support our zero-defect policy, and then we assemble and test every transmission product we ship from our plant.

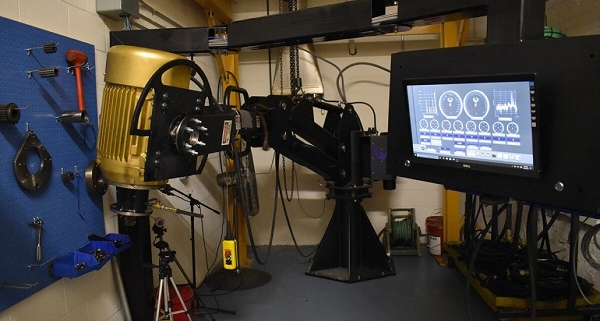

To further enhance these capabilities, Cotta made the investment in an all-new test lab that went operational in 2015. Our state-of-the-art gearbox test facility includes three programmable test cells:

HIGH SPEED TESTING:

- 500 HP horizontal input (3600 RPM)

- 8′ x 11′ x 8.5′ test area

- 25,000+ RPM Input speeds

- 2-150 GPM temperature-controlled oil lubrication system

- Multi-channel FFT spectrum analysis

LOW SPEED TESTING:

- 20 HP horizontal input

- 7′ x 16′ x 7′ test area

SPECIAL PURPOSE TESTING:

- 30 HP fully-adjustable orientation input

- 7′ x 19′ x 7′ test area

OUR TEST LAB ALSO FEATURES:

- Remote shifting

- Fully shielded and interlocked area

- Up to 5-ton crane capacity

- Temperature, pressure, flow, vibration, load, sound, and audiovisual surveillance with DVR

Our test lab facility is just one more reason why customers choose to work with Cotta. Contact Cotta for more information at 608-368-5600 or email sales @cotta.com.

Leave a Reply

Want to join the discussion?Feel free to contribute!